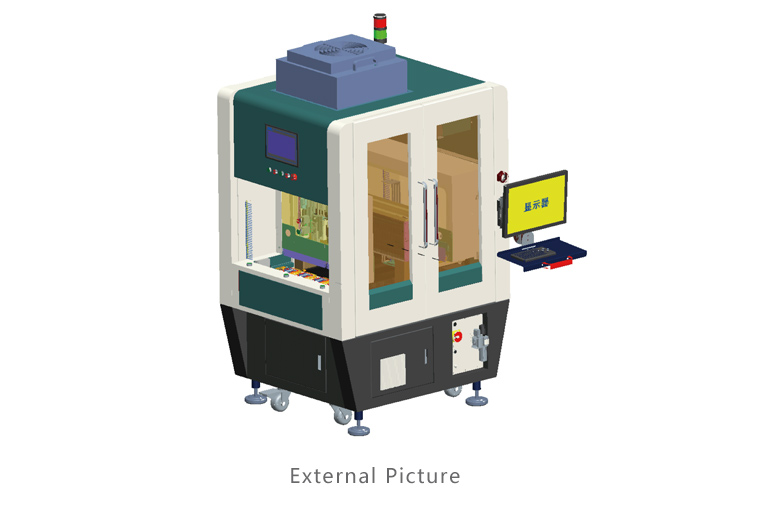

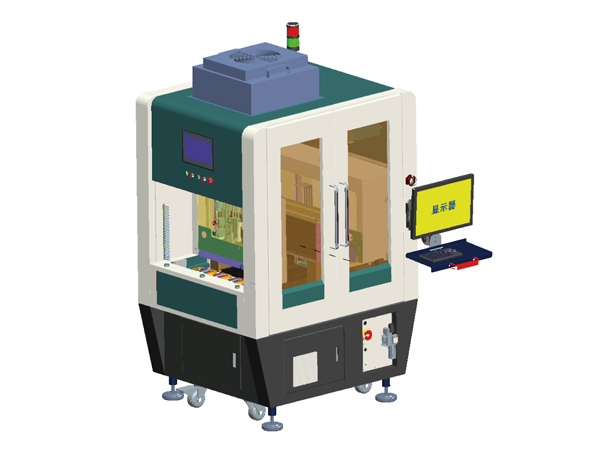

Plasma Cleaning Machine

PLC and touch screen control, audible and light alarms, and visual display

Stepper motor and timing belt driver

A rotating head spray gun

An online tracking system that communicates with all equipment pieces

Can be programmed online

| Equipment Model |

PL-500 |

|

Equipment Direction |

Left to right |

|

Dimensions |

L1.05m × W1.46m × H2.08m |

|

Maximum Board Size |

L500 × W500mm |

|

Minimum Board Size |

L200 × W200mm |

|

Track Height Range |

900 ± 20mm |

|

Transportation Speed |

0~1m/min |

|

XY Drive Mode |

Servo motor + fully sealed linear module |

|

Widening Range / Method |

50~500mm manual adjustment |

|

Maximum Operating Speed |

X/Y axis 600mm/s |

|

Yield |

With 10 " cover as standard, UPH150 |

|

Control Method |

PLC+HMI |

|

Positioning Accuracy |

± 0.02mm |

|

Repeatability |

± 0.01mm |

|

FFU Filtration Accuracy |

0.3 μm , 99.999% |

|

Plasma Spray Gun Width |

30mm |

|

Communication Interface |

SMEMA |

|

Exhaust Volume |

1000m³/h |

|

Working Pressure |

0.3-0.5MPa |

|

Power Supply |

220V single phase, 50/60HZ, 1.5Kw |

|

Color |

Computer gray |

|

Weight |

700Kg |

Function:

Can be used for plasma cleaning of parts in printing and packaging, consumer electronics,plastic, glass, automotive, medical, metal and other industries.

Features:

1、PLC and touch screen control, audible and light alarms, and visual display.

2、Stepper motor and timing belt driver.

3、A rotating head spray gun.

4、An online tracking system that communicates with all equipment pieces.

5、Can be programmed online.

6、Surface Activation: greatly improves the wetting properties ofthe surface.

7、Cleaning: removes dust and oil to finely clean and remove static.

8、Coating: provides a functional surface by surface coating treatment.

9、Improve the adhesion of the surface.

10、Improve the reliability and durability of surface bonding.