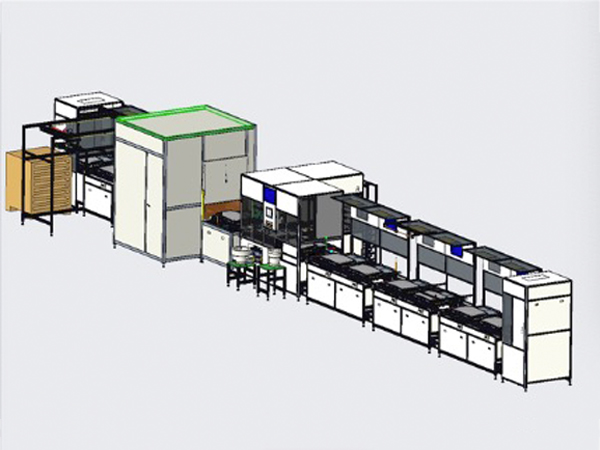

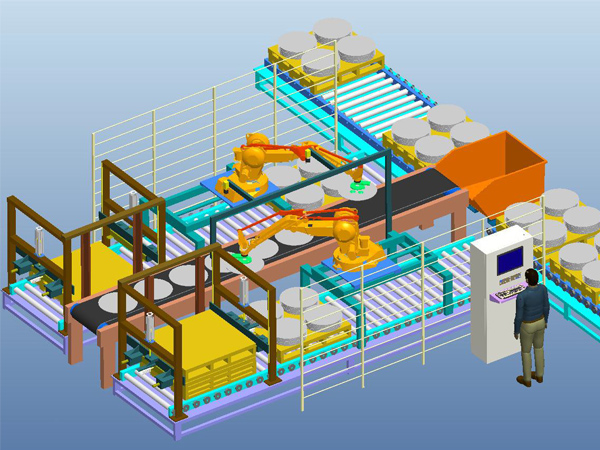

Test Paper Roll Cutting, Bottling, Code Disc Automation System

This machine is mainly for new products developed by reagent card roll cutting + desiccant + automatic bottling + code disc, which fully meets the requirements of automatic roll cutting, bottle capping, bottling, air tightness detection, code disc integrated automatic movement . After the vacuum test, the sealing is firm without air leakage, the appearance of the sealed bottle is beautiful, completely replacing the troublesome process of manual bottling and manual sealing, the production efficiency is greatly improved, and a lot of labor costs are saved

| Pick and place accuracy |

±0.02mm |

|

Beat |

5~6S/bottle |

|

Air pressure |

0.6mpa(Add adjustable air valve) 、Vacuum negative pressure value is greater than65kpa |

|

power supply |

AC220V 50HZ 10A(power:2200W) |

|

Dimensions |

approximately3600㎜(L)×1500㎜(W)×1900㎜(H ) |

Basic Introduction:

This equipment can automatically complete the test strip feeding-> rolling cutting-> receiving-> abnormal and defective product handling-> automatic bottle supply, cap supply-> automatic bottle feeding and capping-> automatic filling to the week after bottling Turntable. The whole process needs to include CCD deviation correction in the feeding section, automatic rejection of defective marks, CCD photographing and abnormal alarm after rolling, and CCD detection in place.

Functional Module:

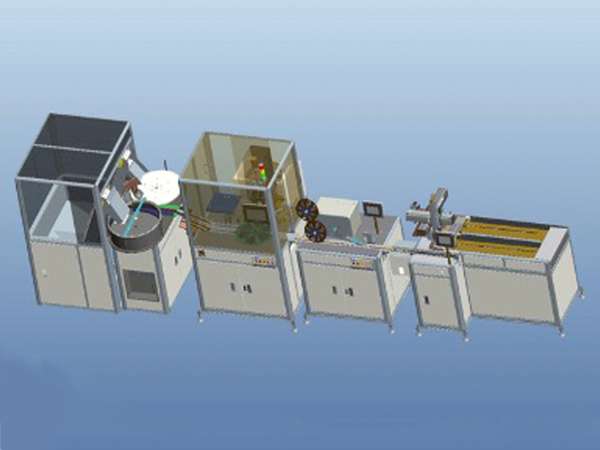

1、Feeding-cutting-receiving module

2、Conveying modules such as belt conveyor and re-inspection

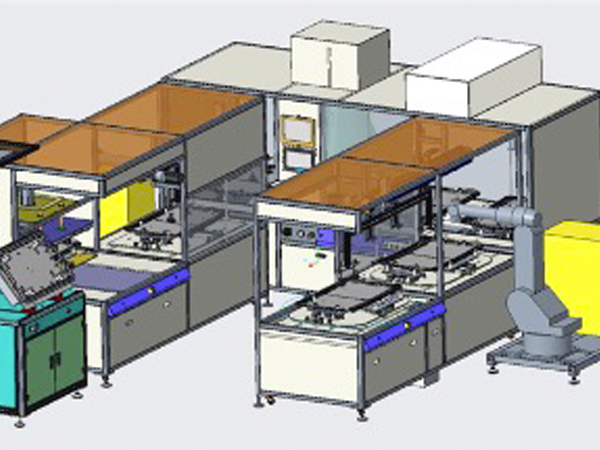

3、Test strip into the bottle module

4、Bottle unscrewing, cap unscrewing and capping modules

5、Code Module