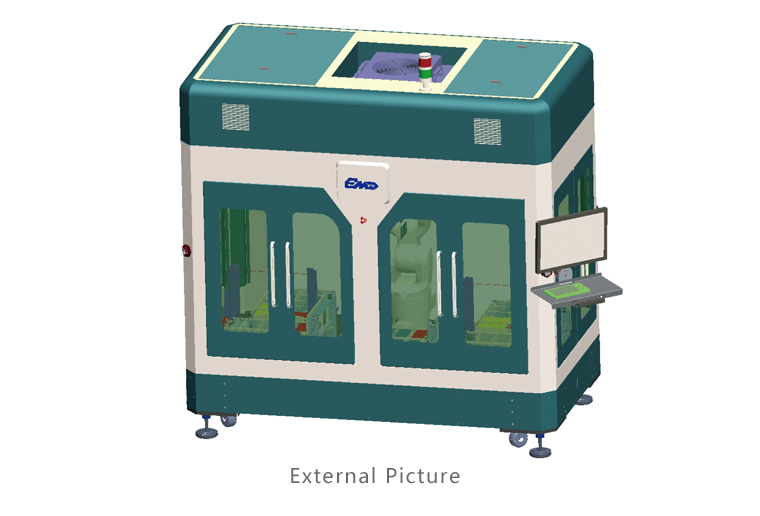

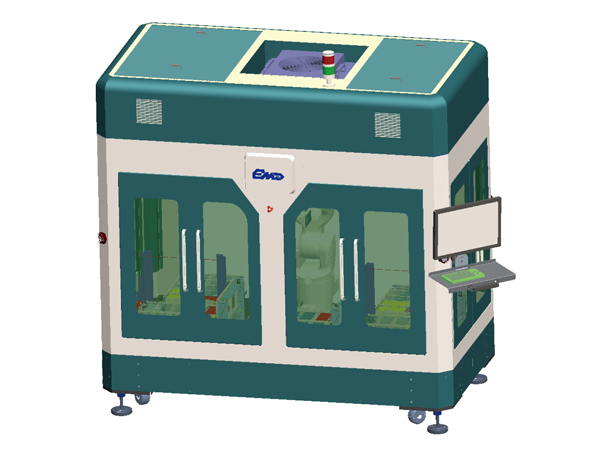

Inkjet Printing Machine

The machine integrates an industrial computer,motion control card, audible and visual alarms,and visual display

A servo motor and ball screw drive give the machine precise position control and fast response

The machine is equipped with a fan-shaped inkjet valve which can be sprayed vertically and horizontally

| Equipment Model |

PM-500 |

|

Equipment Direction |

Left to right |

|

Dimensions |

L1.05m × W1.46m × H2.08m |

|

Maximum Board Size |

L500 × W500mm |

|

Minimum Board Size |

L200 × W200mm |

|

Track Height Range |

900 ± 20mm |

|

Transportation Speed |

0~1m/min |

|

XYZ drive Mode |

Servo motor + fully sealed linear module |

|

Widening Range / Method |

50~500mm automatic width adjustment |

|

Maximum Operating Speed |

X/Y axis 600mm/s |

|

Yield |

120 units per hour for a 10in standard print |

|

Control Method |

Control card + PC |

|

Positioning Accuracy |

± 0.02mm |

|

Repeatability |

± 0.01mm |

|

FFU Filtration Accuracy |

0.3 μm, 99.999% |

|

Spray Gun |

Devilbiss T-AGPZ |

|

Double Spray Gun System |

Devilbiss T-AGPZ (optional) |

|

Gun Caliber |

0.5/0.7/1.0mm (optional) |

|

Ink Thickness |

6 μ m or more |

|

Ink Thickness Uniformity |

≦ 10% |

|

Coating Capacity |

500ml |

|

Paint Detection |

Precision pressure sensor |

|

Communication Interface |

SMEMA |

|

Air Supply |

2000m ³ / h |

|

Exhaust Volume |

1500m ³ / h |

|

Working Pressure |

0.3~0.5MPa |

|

Power Supply |

220V single phase , 50/60HZ, 1.5Kw |

|

Color |

Computer gray |

|

Weight |

800Kg |

|

Bar Code Scanning Code |

Optional |

|

Spray Gun Cleaning |

Ultrasonic device (optional) |

Function:

Machine uses inkjet technology for a variety of application including: 2.5D , 3D glass cover inkjet,LOGO , I-CON inkjet, protective glue spraying, insulating rubber spraying, etc.

Features:

1、The machine integrates an industrial computer,motion control card, audible and visual alarms,and visual display.

2、A servo motor and ball screw drive give the machine precise position control and fast response.

3、The machine is equipped with a fan-shaped inkjet valve which can be sprayed vertically and horizontally.

4、The system is aromatically prompted to add ink from a weight detection sensor response.

5、A computer system is used to monitor and change the pressure of the incoming air stream, after it passes through a high efficiency filter.

6、The outgoing air stream also passes through a filter to catch any ink particles remaining in it.

7、The machine can be programmed online and is easy to operate.