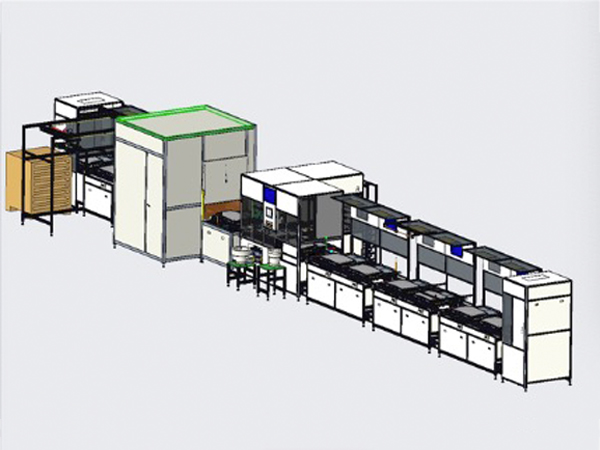

Pill Box Sealing Sticker Labeling Machine

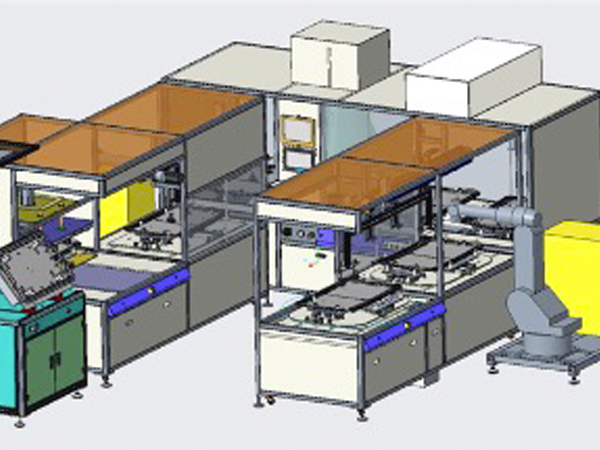

It is suitable for corner sealing and labeling of various packaging boxes, and is widely used in industries such as medicine, daily chemical and logistics. It adopts a flexible box pressing device to ensure the stability of the box body during labeling and greatly improve the labeling accuracy; this model can complete packaging Box upper surface sealing, lower surface sealing, two kinds of diagonal sealing labels, etc., a total of four types of sealing labeling can be achieved; flexible transfer printer or inkjet printer can be selected; the main materials of this model are SUS304 stainless steel and imported aluminum alloy material in line with international standards. The surface of the aluminum alloy is double anodized to prevent rusting.

| Output (pieces / minute) |

50-200 pcs / min (related to material and label size) |

|

Operation direction |

Left in right out or right in left out |

|

Labeling accuracy |

±1.0 mm |

|

Label type |

Stickers, transparent or opaque |

|

Label inner diameter |

76 mm |

|

Label outside diameter |

350 mm(max) |

|

Label size |

Length 10-70mm, height 10-70mm |

|

Labeling object size |

Length 40-90mm, width≤100mm |

|

working pressure |

0.6Mpa |

|

Power supply and power |

220VAC±10% 50Hz,1.2Kw |

|

Applicable environment |

Temperature 5-40 ℃, humidity 15-85% (no condensation) |

|

weight(kg) |

400kg |

|

Machine size |

2200(L) 1300(W) 1500 (H) mm |

|

Remarks |

Accept non-standard customization |

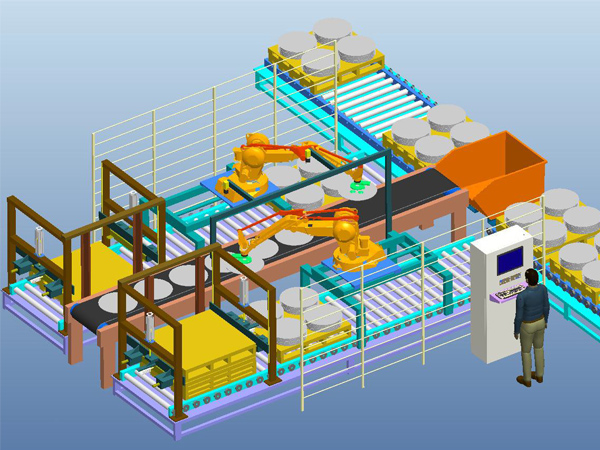

Basic use:

It is suitable for corner sealing and labeling of various packaging boxes, and is widely used in medicine, daily chemical, logistics and other industries.

Features:

1、The overall material of the equipment is stainless steel and aluminum alloy, the mechanism design is stable and easy to operate, and the layout is beautiful.

2、The use of world-renowned electrical components with stable quality

3、The transparent label has no foam and no wrinkle

4、The flexible top pressure device is used to ensure the stability of the box body during labeling, greatly improving the labeling accuracy

5、Up to four types of sealing labeling can be achieved (upper surface sealing, lower surface sealing, two diagonal sealing labels)

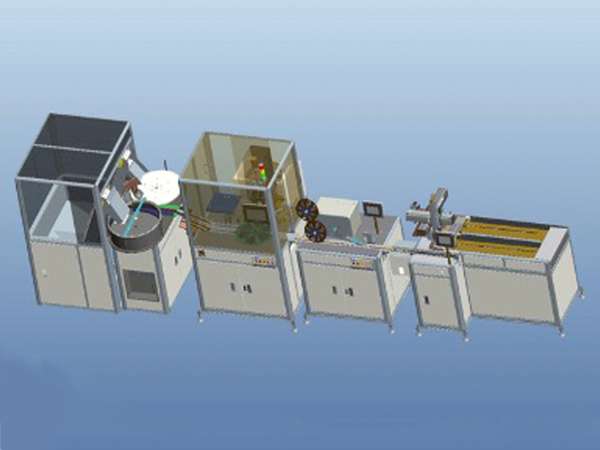

operating system:

1、Multi-functional human-machine operation interface, production counting, parameter adjustment and other visual monitoring.

2、With rich help function and fault display function.

3、It can automatically detect the label length and other functions.

Optional:

1、Flexible hot stamping machine or inkjet printer is optional.

2、Special sensors for transparent and opaque labels are available.

3、Whether the box has the labeling detection and rejection function, and the remaining label alarm function.